Laser interferometers are devices that utilize the phenomenon of light interference to measure displacement and distance with nanometer-level precision. Today, they are widely used across various fields, including semiconductor manufacturing, precision motion control, astronomy, and gravitational wave observation.

This article explains the principles, structure, and application examples of laser interferometers. It also introduces examples of high-precision laser measurements utilizing our products: the “A0020A Laser Line Width Measurement System,” “A0040A Optical Noise Analyzer,” and “A0070A Optical Frequency Analyzer.”

Table of Contents

- What is a Laser Interferometer?

- Understanding the Principles and Equations of Interferometers

- System Configuration of Laser Interferometers

- Applications and Advantages of Laser Interferometers

- Manufacturers and Related Products of Laser Interferometers

- [Case Studies] Achievements in High-Precision Measurement Using SYCATUS Products

- Conclusion: Understand the Mechanism of High-Precision Laser Interferometer Measurement and Implement the Best Product

- Feel Free to Contact Us About Our Products

What is a Laser Interferometer?

A laser interferometer is a device that analyzes the “interference pattern” generated when two laser beams of closely matched wavelengths are combined, enabling the measurement of displacement and other quantities. The state of this interference pattern corresponds to the wavelength of light, allowing for the detection of extremely fine changes, such as nanometer-level displacements. Typically, it employs a structure that splits and recombines the same laser beam.

History and Development of Laser Interferometers

The origins of interferometers date back to the 19th century. The beginning was marked by the advent of the most common optical instrument for interferometry, the Michelson interferometer, invented by Albert Michelson in the 19th century. Michelson and Edward Morley used this interferometer to conduct the famous Michelson-Morley experiment (1887), demonstrating that the speed of light is constant in all inertial frames of reference and disproving the ether theory.

As semiconductor lasers and fiber lasers became common light sources, the stability of laser wavelengths improved, leading to dramatic increases in measurement accuracy and reproducibility. In recent years, laser interferometers have been incorporated into gravitational wave detectors like the U.S. LIGO, further expanding the applications of optical interference technology.

Reference:

Understanding the Principles and Equations of Interferometers

Measurement Principles of Laser Interferometers

Interferometers calculate the displacement or distance of an object based on the phase difference arising from the path difference between the reference light and the reflected light. Since this phase difference manifests as integer multiples or fractional multiples of the wavelength, the wavelength of light serves as the standard for precision. Therefore, the wavelength and stability of the laser used significantly impact the interferometer's accuracy.

Equations for Phase Difference and Wavelength

Phase difference arises from differences in the distance or path traveled by light waves and determines the measurement accuracy of an interferometer. The phase difference Δφ is determined by the wavelength λ and the path difference ΔL, expressed by the following equation:

Δφ = (2π / λ) × ΔL

Here, the unit of Δφ is radians, λ is the wavelength of light, and ΔL is the difference in path length between the two light paths. This equation enables the high-precision derivation of the displacement amount of the target object.

However, to accurately derive the displacement amount, multiple factors such as the stability of the laser wavelength, reflectivity, and the Straightness of light beams also influence the result, so these must also be appropriately managed.

Factors Enabling High-Precision Measurement

To achieve high-precision measurements, it is essential to eliminate external environmental influences as much as possible. For example, temperature changes, vibrations, variations in the refractive index of the optical path medium, and differences in the reflectivity of optical components can all potentially affect measurements. Design and environmental management aimed at minimizing such disturbances are key to supporting stable, high-precision measurements.

System Configuration of Laser Interferometers

A typical laser interferometer system consists of a laser light source, an optical splitter, mirrors, and a photodetector. It interferes the reflected light, detects changes with the photodetector, and quantifies the results through signal processing.

The main components of the interferometer have the following roles:

- Laser source: Generates laser light with a stable wavelength

- Optical splitter: Splits or combines the laser light into two optical paths

- Mirror: Sets the direction of the optical path by reflecting the laser light

- Photodetector: Converts the interfered laser light into an electrical signal

Applications and Advantages of Laser Interferometers

Where Are They Used?

Laser interferometers enable displacement detection at the nanometer level, making them widely used in high-precision positioning and microfabrication. Their non-contact nature and high responsiveness also make them ideal for equipment feedback control and motion control.

Their applications span diverse fields, including stage position control in semiconductor manufacturing equipment, module inspection in optical communication devices, and mirror alignment in astronomical telescopes.

Additionally, by fixing the interferometer's distance, fluctuations in the laser's optical frequency or phase can be detected. Interferometers play a crucial role in communications utilizing optical phase modulation.

Differences from Other Measurement Systems

Compared to various measurement methods such as contact measurement, ToF measurement, electrical displacement sensors, and camera-based measurement, laser interferometers are generally recognized as a measurement method offering high resolution, good repeatability, and stability.

Laser interferometers are particularly favored for achieving high-precision measurements in processes requiring the detection of minute variations in position or distance. They also feature high compatibility with measurement systems within overall equipment control systems and offer broad applicability.

Manufacturers and Related Products of Laser Interferometers

Major domestic and international manufacturers developing and providing laser interferometers include SYCATUS, ZYGO, Renishaw, Keyence, and Keysight, each offering products with distinct features.

SYCATUS's “Laser Line Width Measurement System”

SYCATUS provides advanced technologies enabling precise optical measurements.

SYCATUS's A0020A Laser Line Width Measurement System is a measurement system for evaluating laser line width using the conventional delay interferometer method. Laser line width evaluation is essential for the development, manufacturing, and quality control of lasers for optical communications.

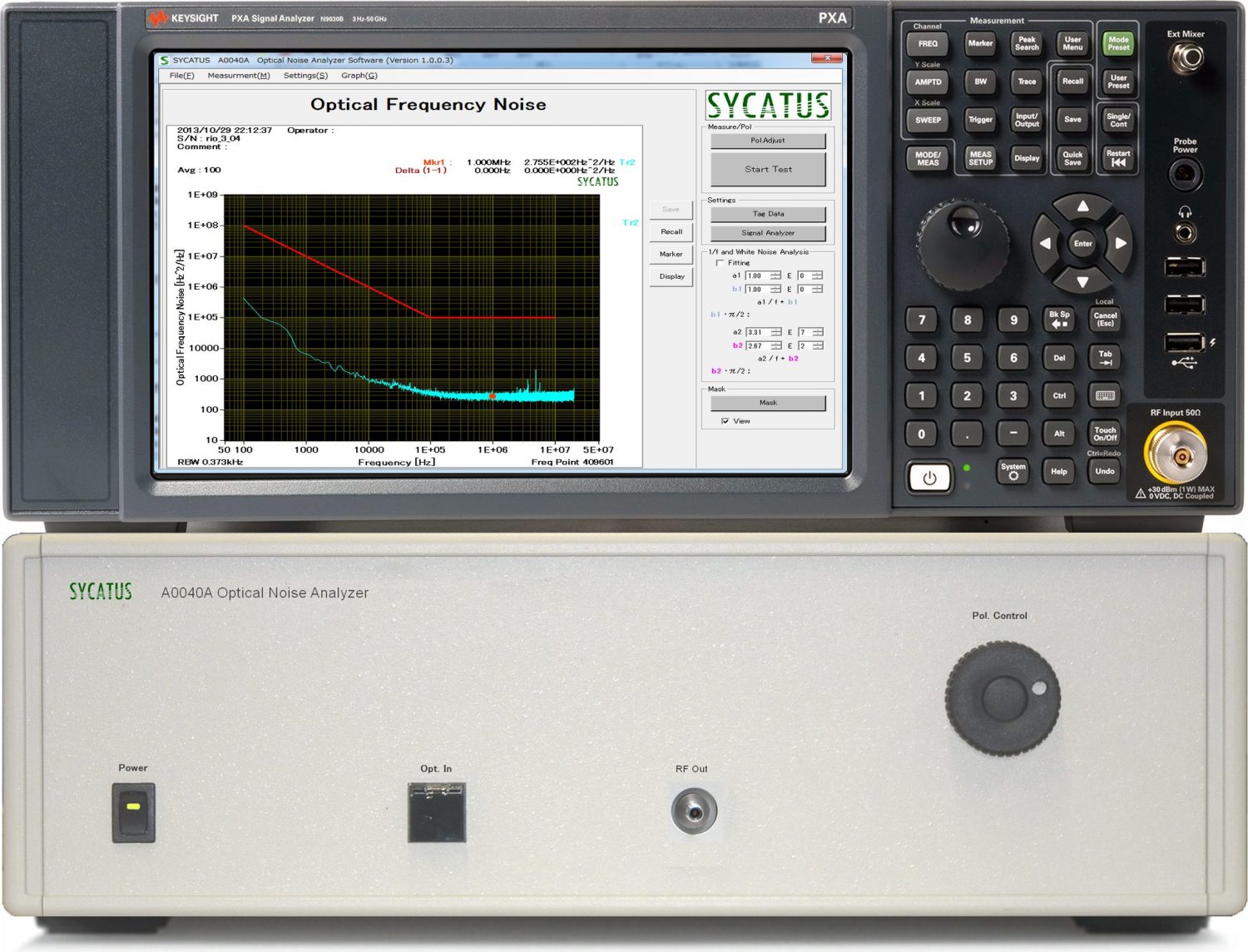

Additionally, the A0040A Optical Noise Analyzer is an advanced measurement system that utilizes a specialized interferometer to analyze laser line width as optical frequency noise power spectral density.

Furthermore, the A0070A Optical Frequency Analyzer is a groundbreaking system that uses the same interferometer as the A0040A to measure the optical frequency modulation of lasers used in applications such as FMCW LiDAR in real time along the time axis, like an oscilloscope.

These products enable easy implementation of highly accurate measurements by the combination with high-sensitivity, low-noise optical test sets and Keysight Technologies signal analyzers.

Product Pages:

- A0020A Laser Line Width Measurement System│SYCATUS

- A0040A Optical Noise Analyzer│SYCATUS

- A0070A Optical Frequency Analyzer│SYCATUS

Related Blog: Fundamentals in Light Measurement: What is “Laser Line Width”?

ZYGO's “Laser Interferometer”

ZYGO is recognized as a pioneer in precision optical measurement, particularly renowned for its optical coating thickness measurement capabilities.

ZYGO's laser interferometers enable the industry's most demanding measurement applications, spanning semiconductors and lithography to satellite imaging systems, cutting-edge consumer electronics, defense infrared (IR) and thermal imaging systems, and ophthalmic medical devices.

ZYGO offers a broad portfolio of interferometers, including the highest resolution interferometers developed for evaluating mid-spacial frequency characteristics. The lineup also includes cost-effective devices for manufacturing and units optimized for harsh environments.

Product Page: レーザー干渉計|ZYGO

Renishaw's “RLE Fiber Laser”

Renishaw is a world-leading company in engineering and scientific technology, specializing in high-precision measurement technology and healthcare.

Renishaw provides a diverse range of interferometric laser encoders, serving clients from large aerospace centers to OEM machine manufacturers in the high-precision semiconductor industry. For example, Renishaw's RLE Fiber Laser is a state-of-the-art homodyne laser interferometer system, developed in-house by Renishaw specifically for positioning feedback.

Reference:

Keyence's “Laser Displacement Sensor”

Keyence is a comprehensive manufacturer of factory automation (FA) equipment. Since its founding in 1974, it has continuously created new value. Today, its high-value-added products, including FA sensors, are utilized across a wide range of industries such as automotive, semiconductor, electronics, electrical equipment, communications, machinery, chemicals, pharmaceuticals, and food. Keyence operates 250 locations across 46 countries, contributing to manufacturing sites at 350,000 companies worldwide.

Keyence's 1D laser displacement sensors are primarily classified into two types. One is the ‘confocal method’, which uses coaxial laser beams for both emission and reception. The other is the ‘triangulation method’, where the optical paths for emitting and receiving the reflected light form a triangle. You can select the optimal laser displacement sensor for measuring dimensions such as height, thickness, and width based on the application, workpiece material, and installation distance.

Company & Product pages:

Keysight's “Laser Interferometer and Calibration System”

Keysight Technologies is a global leader in the development and manufacture of laser interferometers and laser calibration systems, advanced electronic measurement systems, high-precision optical components, compound monolithic optics (CMO), and optoelectronic systems for the most demanding measurement applications.

Keysight's laser interferometers and laser calibration systems deliver high precision across a wide dynamic range, position measurement capabilities across multiple degrees of freedom, and the highest accuracy available for both airborne and vacuum systems.

Reference: Laser Interferometers and Calibration Systems | Keysight Technologies

[Case Studies] Achievements in High-Precision Measurement Using SYCATUS Products

1. A0020A Laser Line Width Measurement System

SYCATUS's A0020A Laser Line Width Measurement System is a simple and accurate measurement system for measuring the line width of laser diodes. Combined with Keysight's signal analyzer, it enables easy and stable measurements.

Key Features

- Laser line width measurement down to 40kHz

- Supports a wide wavelength range in the C/L bands

- Integrated interferometer and photodetector in a single housing

Customer Case Study

Communication Semiconductor Laser Manufacturer: “Ideal for laser quality control”

We perform line width measurements as part of laser chip quality control. The A0020A Laser Line Width Measurement System enables stable and easy measurements, enhancing the efficiency and reliability of our quality control process.

2. A0040A Optical Noise Analyzer

The A0040A Optical Noise Analyzer is the industry's first solution for evaluating the optical frequency noise spectral density of lasers.

It analyzes 1/f noise, white noise, and Lorentzian bandwidth in lasers used in digital coherent transmission systems and CPO. It can detect spurious noise from dither and EMI required for ITLA or ELSFP development. Measurements are simple, stable, and fast, requiring no reference laser source or frequency tuning.

Key Features

- Measures optical frequency noise as power spectral density

- Analyzes 1/f noise, white noise, and Lorentz bandwidth

- High sensitivity of 0.006 Hz2/Hz by standard mode and 0.0006 Hz2/Hz by high sensitivity mode at 1 MHz

- Incorporates same functionality of conventional delay self-heterodyne interferometers as A0020A

Customer Case Study

Digital Coherent Transceiver Manufacturer: “Accurately captured EMI effects and significantly suppressed noise through design improvements”

We understood that EMI generated by electronic circuits affected line width performance, but the specific causes remained unclear.

By utilizing the A0040A's line width spectrum analysis, we identified EMI sources and revised circuitry and implementation. This enabled us to maintain narrow line width characteristics while also shortening the time to market for our products.

Conclusion: Understand the Mechanism of High-Precision Laser Interferometer Measurement and Implement the Best Product

Laser interferometers represent an outstanding technology capable of measuring minute displacements and distances with high precision and non-contact. Their diverse applications and technological evolution are anticipated to continue expanding.

In the fields of optical communications and optical sensing, utilizing SYCATUS measurement instruments employing laser interferometer technology—such as the “A0020A Laser Linewidth Measurement System,” “A0040A Optical Noise Analyzer,” and “A0070A Optical Frequency Analyzer”—enables improvements in measurement reliability and design efficiency.

For companies interested in our various measurement solutions or products, please feel free to contact us.

Feel Free to Contact Us About Our Products

As a pioneer in optical measurement for optical communications and optical sensing, SYCATUS has provided integrated hardware and software systems for measurement for over 20 years.

We will continue to deliver innovative optical measurement technologies developed based on expertise, uniqueness, and accuracy to the world.

We also provide expert advice to address various questions about optical measurement and concerns regarding system equipment implementation.

Our specialized staff will assist you in resolving diverse issues related to optical measurement.